OE Weak Points

The Weak Points in Many OE Coil Designs Lead to Product Failure

Our engineers identify the OE flaws

We design the BWD® coil to overcome these flaws

We manufacture a more reliable, better performing ignition coil

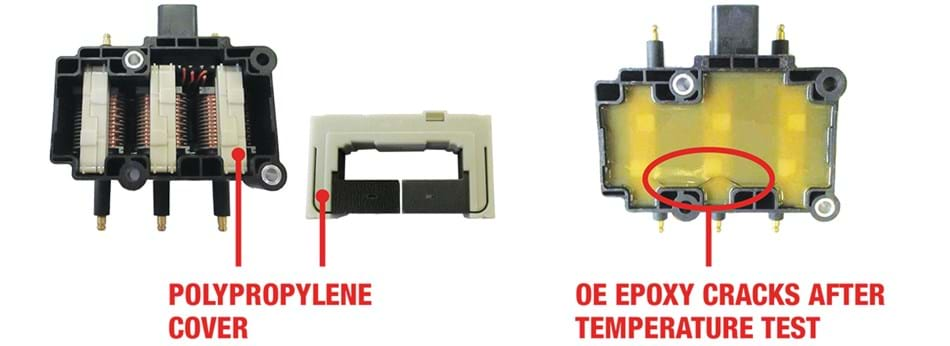

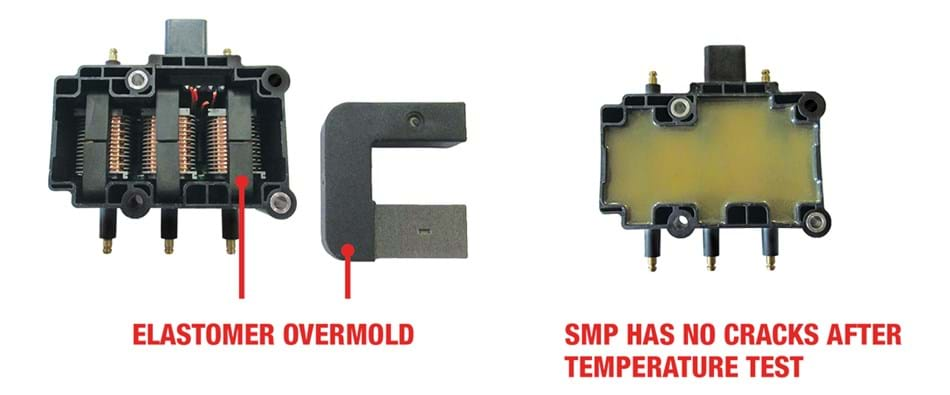

OE Design Flaw: Polypropylene Cover

The OE polypropylene cover on steel core leads to epoxy cracking, moisture intrusion, degraded performance and eventual coil failure.

SMP Solution: Elastomer Overmold

The BWD® design overmolds the iron core with TPE elastomer preserving coil integrity.

Source: SMP Poland Testing Lab, 2018

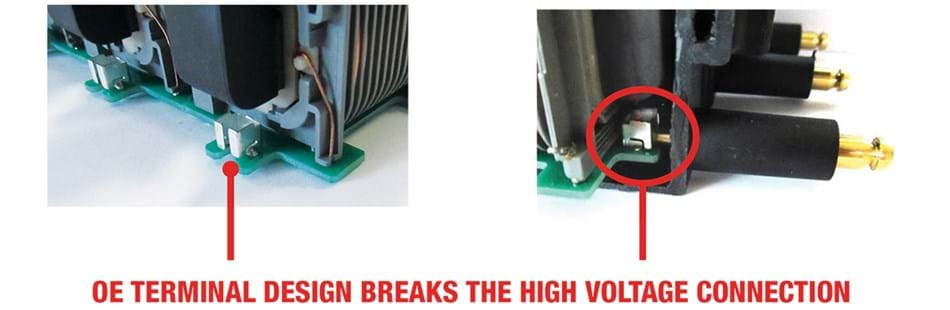

OE Design Flaw: Terminal Deforms

The OE metal terminal deforms while the epoxy cures causing the high voltage connection to fail.

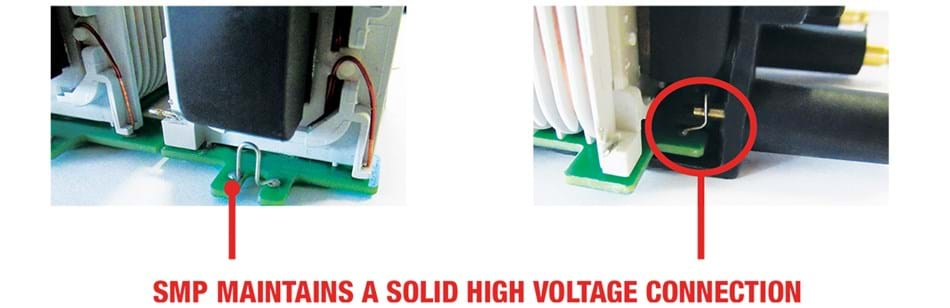

SMP Solution: Spring Terminal Design

BWD® engineering features a spring terminal design to maintain a solid high voltage connection for top performance and long service life.

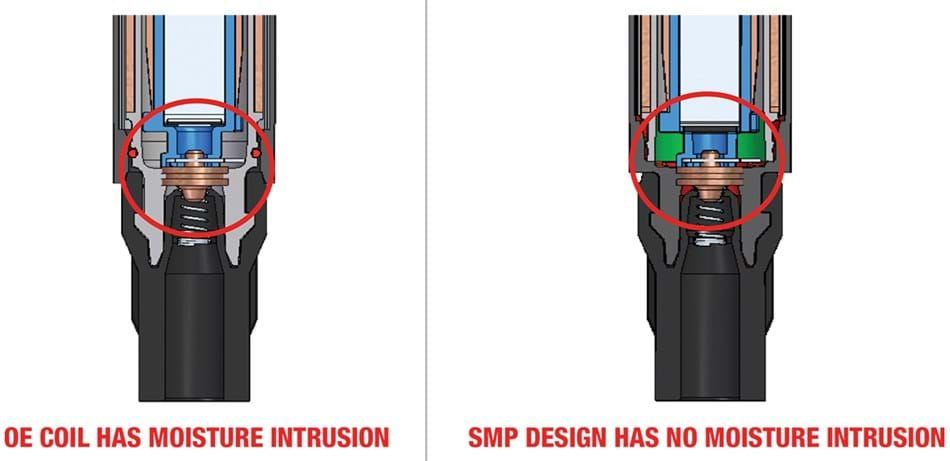

OE Design Flaw: O-ring Design

When the OE O-ring breaks down it allows moisture intrusion which impedes performance and shortens coil life.

SMP Solution: Eliminate O-ring Housing

The BWD® one-piece design with no O-ring housing prevents moisture intrusion, ensuring peak coil performance and long service life.

SMP designs improvements to numerous OE pencil coils