- Featured

- Overview

-

Sensors

- Air Charge / Manifold Temperature Sensors

- Accelerator Pedal Sensors

- Anti-lock Brake (ABS) Sensors

- Battery Current Sensors

- Brake Pad Wear Sensors

- Camshaft Sensors

- Crankshaft Sensors

- Coolant Temperature Sensors

- Knock Sensors

- Manifold Absolute Presure (MAP) Sensors

- Mass Air Flow (MAF) Sensors

- Steering Angle Sensors

- Throttle Position Sensors

- Transmission Input/Output Sensors

- Vehicle Speed Sensors

- Yaw Rate Sensors

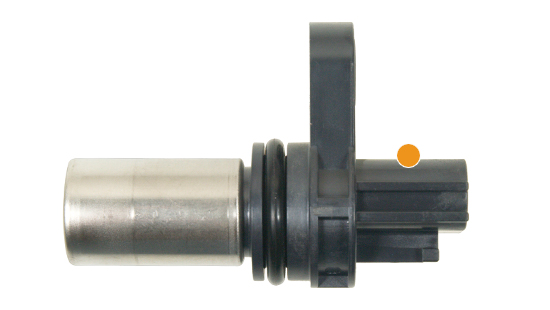

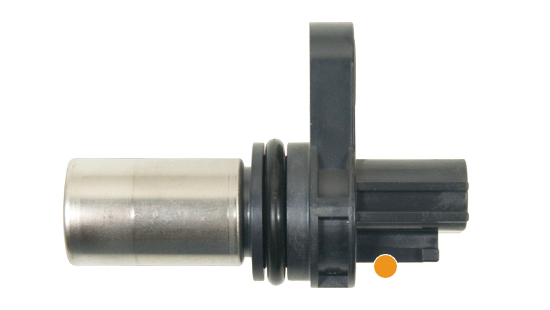

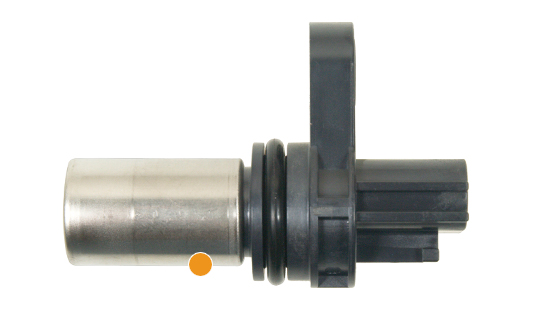

Camshaft Sensors

The Coverage and Quality You Need

Our comprehensive line of Camshaft Position Sensors has applications for both domestic and import applications. With hundreds of camshaft sensors in our line, we supply comprehensive coverage for all makes, including Chrysler, Ford, GM, Honda, Mercedes-Benz, Nissan, Toyota, and Volkswagen.

To ensure quality, we manufacture our BWD® and Intermotor® camshaft position sensors at our IATF 16949-certified facility in Reynosa, Mexico. To make sure they perform and last, we put each unit through end-of-line timing, pulse width, and signal amplitude testing. That means you’ll get a sensor that protects against over-voltage, under-voltage, reverse-voltage, and short circuits, and that maintains accuracy during heavy-duty shock, vibration, and maximum temperature conditions.

Interested in learning more about this product category? Contact your local BWD rep.

Designed with Premium Components

To protect against failure, we manufacture camshaft sensors using premium components, including:

- Fluorocarbon rubber oil seal ensures secure fit

- Integrated waterproof connector ensures lasting performance

- Sealed construction withstands extreme under-hood conditions

- Advanced circuitry provides immunity from EMI (such as stray electro-magnetic fields, power spikes, and static electricity) that meets ISO standards

Plus, to ensure durability and longevity, we subject each camshaft sensor to extensive end-of-line testing.

Our 48-Hour Vibration Test Ensures Durability

Our camshaft position sensors undergo 48-to-64-hour vibration testing across three different planes to ensure performance under the harshest conditions. We also subject each sensor to extensive end-of-line timing, pulse width, and signal amplitude testing.

What Our Testing Means for You

- Protect against over-voltage, under-voltage, reverse-voltage, and short circuits

- Maintain accuracy during heavy-duty shock, vibration, and maximum temperature conditions

About Cam Sensors

Typically located in the engine’s cylinder head, camshaft sensors determine which cylinder is firing in order to establish injector synchronization and coil firing sequence in DIS systems. The sensors can fail due to extreme temperature, contamination, and wear and tear.

-

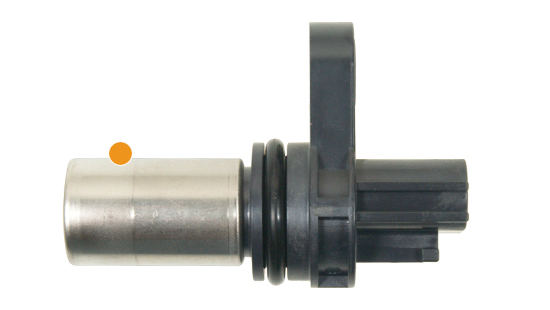

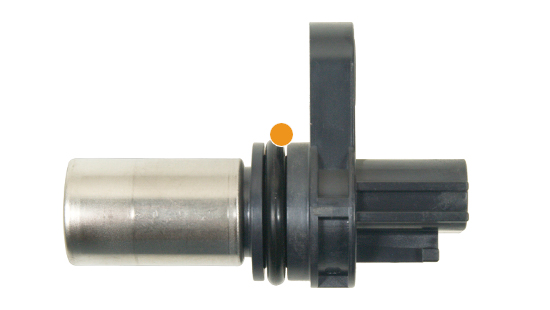

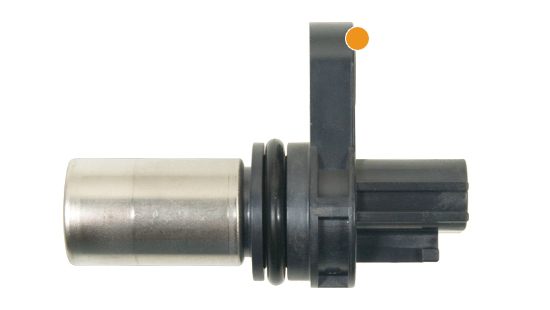

Sealed metal casing prevents oil intrusion

-

Fluorocarbon rubber oil seal ensures secure fit

-

Rotated mounting ear matches latest OE-design

-

Sealed construction withstands extreme under-hood conditions

-

Integrated waterproof connector ensures lasting performance

-

Advanced circuitry provides immunity from EMI (such as stray electro-magnetic fields, power spikes, and static electricity) that meets ISO standards

Tech Tip: Replace Cam/Crank Sensors Together

- With ever-increasing fuel economy regulations, modern engines are using VVT systems with multiple camshafts

- A typical DOHC engine will have 2-4 camshaft sensors as well as a crankshaft sensor

- If one sensor fails, it likely means that the other sensors are nearing the end of their service life, too

- To ensure proper performance, we recommend replacing the cam/crank sensors together