BWD Heavier-Duty Ignition Coils

Heavier-Duty Ignition Coils

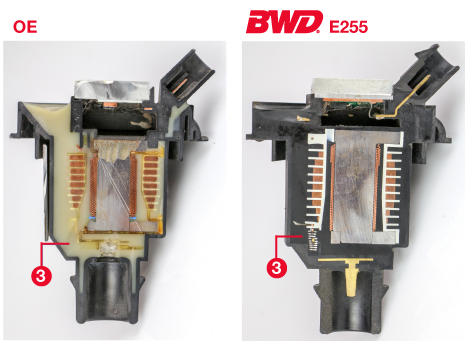

BWD’s new heavier-duty ignition coils are the product of superior design, manufacturing, and testing. See below how our BWD Heavy-Duty Coil compares to the OE.

Product of Superior Design

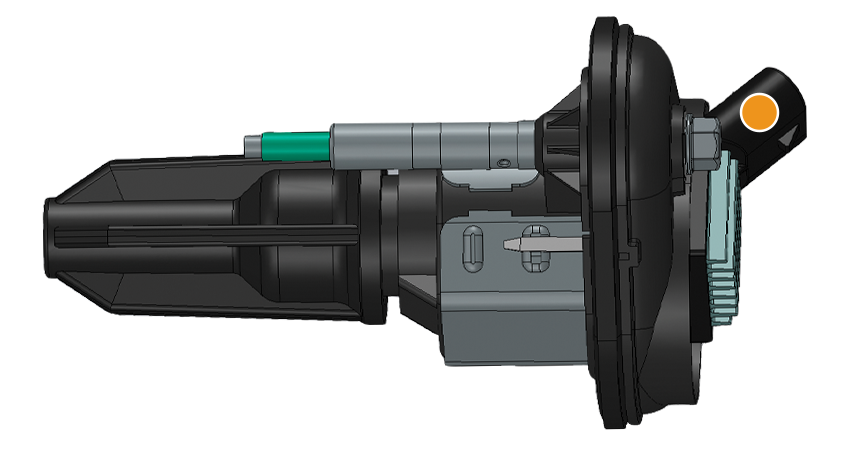

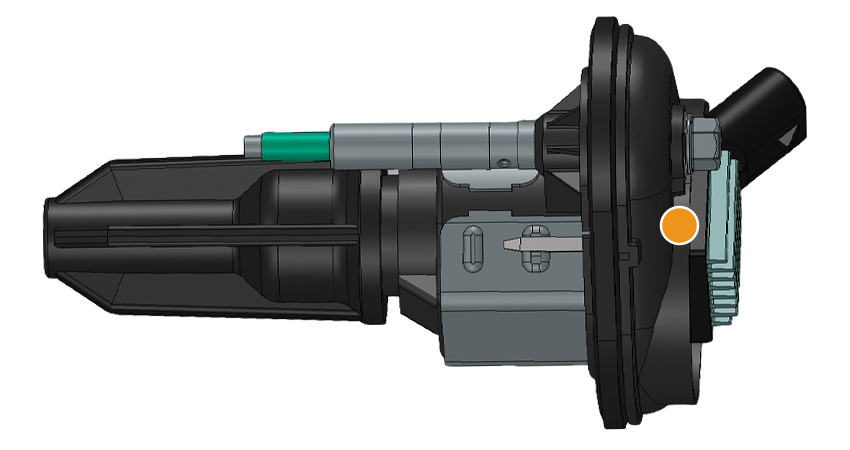

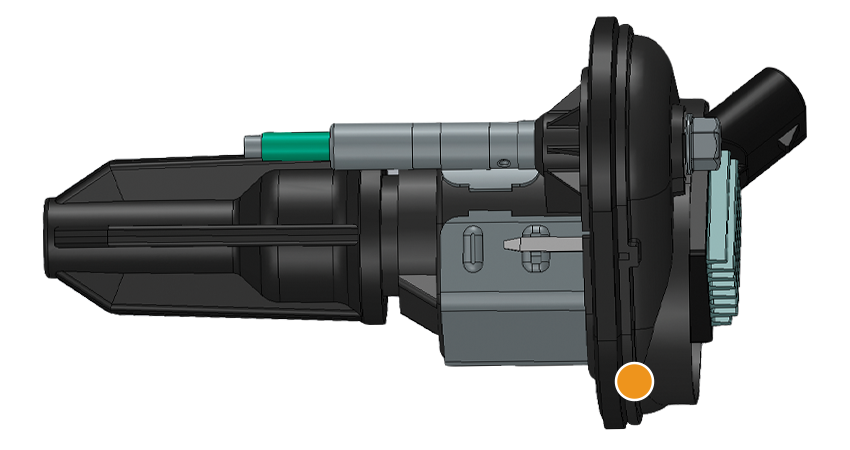

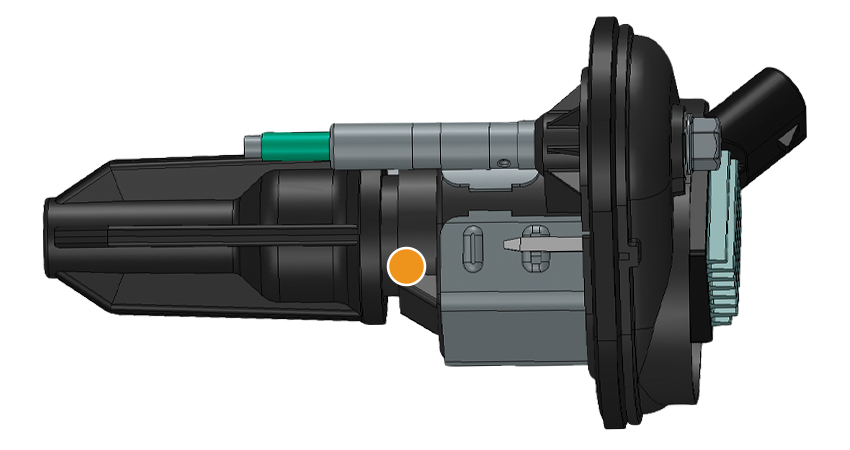

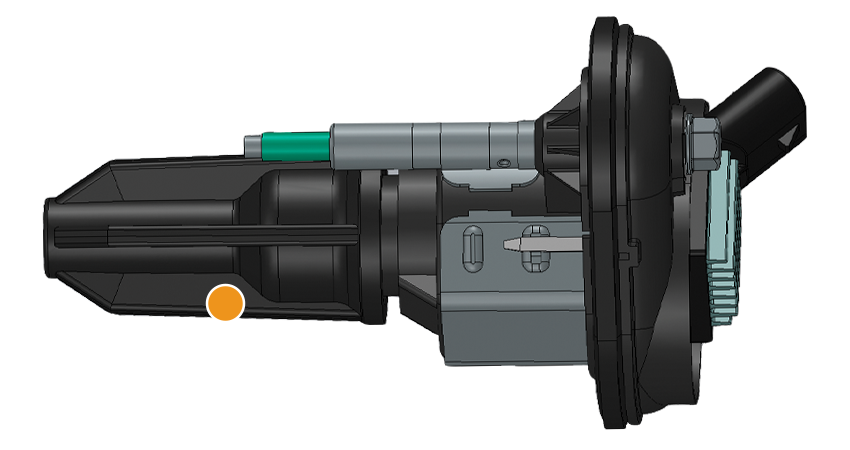

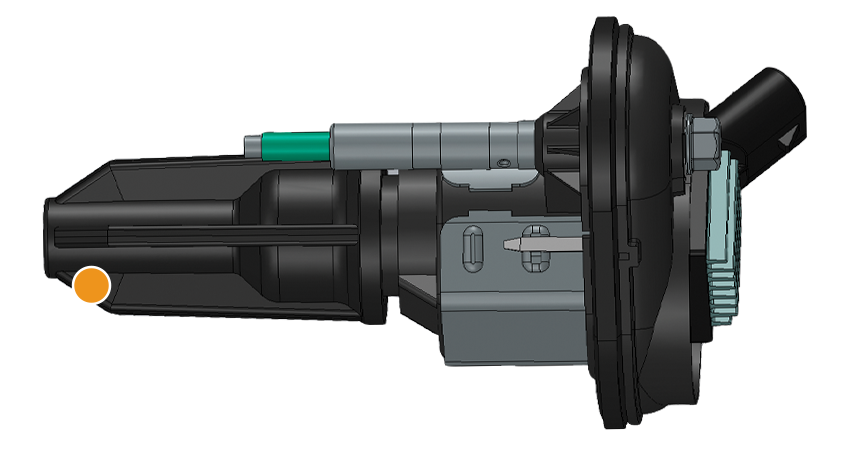

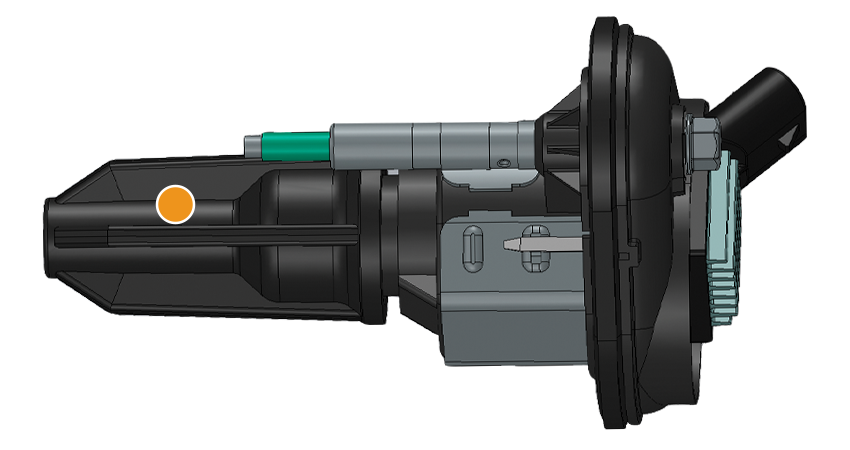

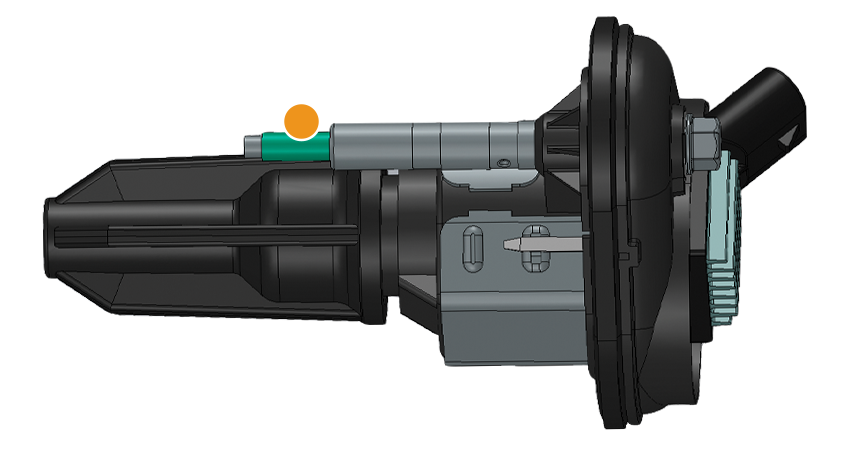

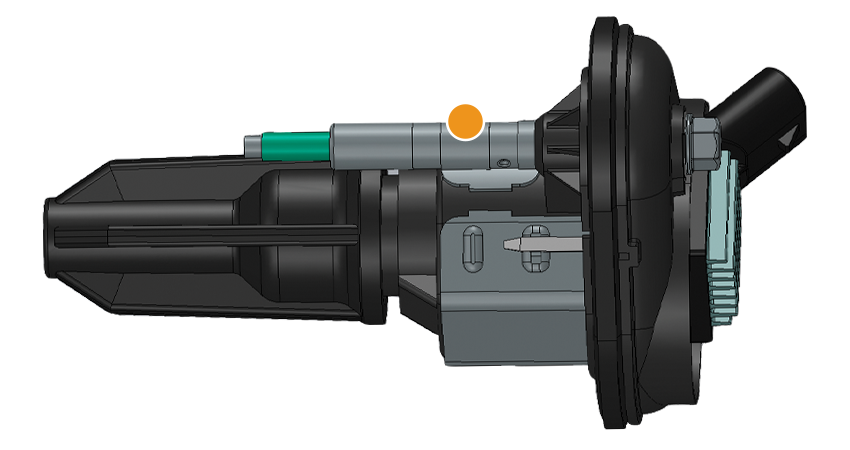

BWD’s new heavier-duty ignition coils are the product of superior design, manufacturing, and testing. For example, take our E255, one of the many new heavier-duty ignition coils in our line.

-

Advanced thermoplastic coil connector ensures proper connection and resists fractures caused by heat and thermal cycling

-

Primary (23 gauge) and Secondary (43 gauge) copper wire ensure high-voltage availability for peak performance while reinforced bobbins prevent voltage flashover for extended service life

-

High-impact housing material ensures superior bond to epoxy for longer life in all operating conditions

-

Internal, neodymium permanent magnet core surrounded by grain-oriented, magnetic-laminated steel maximizes high-voltage output at all engine RPMs and loads

-

Tested at extreme engine performance condition at 7200 RPM

-

Engineered and tested to match or exceed OE for spark energy output, impedance, and durability

-

High-temp boot prevents high-voltage leaks, while stainless-steel spring with internal ferrite noise suppressor prevents radio frequency interference (RFI)

-

Isolator manufactured using high voltage-resistant thermoplastics to prevent premature coil failure

-

Copper wires using higher insulation grade ensure heat resistance and prevent high voltage breakdown

-

Optimum wire distribution developed by extensive testing ensures superior functional parameters and durability

BWD vs OE Coil Comparison

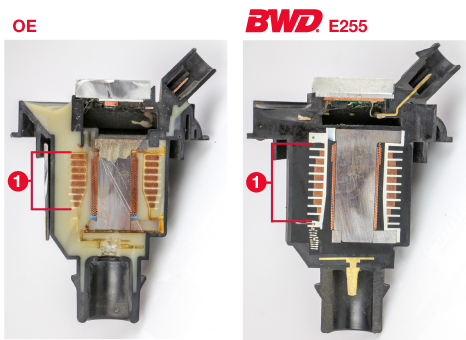

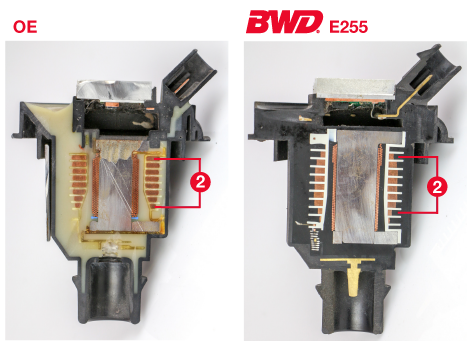

To see what makes our BWD® coils superior, we conducted a visual cutaway comparison against the OE. Here’s what we found:

-

OE: 8 primary winding sections.

BWD: With 10 primary winding sections, our design reduces the height of each section’s winding to decrease the risk of breakage between sections.

-

OE: Uneven number of winding turns.

BWD: Our barrel winding distribution precisely reduces the number of turns in the first and last two sections to reduce the voltage gradient. When combined with our higher G2 insulation grade, our winding distribution lowers the risk of breakage within the winding.

-

OE: Potted using “yellow” epoxy system.

BWD: When compared to common “amber/yellow” epoxy systems, our “black” epoxy system features nearly 40% higher insulation resistance to voltage breakdown.

Basic Manufacturing at Our State-of-the-Art Facility

Our IATF 16949 and ISO 9001-certified facility in Bialystok, Poland, is dedicated to the highest quality manufacturing. Spanning 105,000 square feet, the facility serves as a basic design and engineering center for our BWD® ignition coils. The facility employs lean manufacturing methods such as the 5S philosophy and features a vertically integrated manufacturing process with multi-spindle winding, injection molding, potting, curing, and welding. At the end of the day, the parts that leave our SMP Poland facility are manufactured for superior performance and durability.

End-of-life testing confirms polarity and continuity to ensure superior function

Semi-automatic bobbin winding speeds up the manufacturing process

We manufacture 6 million coils each year