Manufactured in our IATF 16949-certified facility, our Crankshaft Position Sensors feature matching connectors and tin-plated brass terminals to ensure an accurate, watertight connection to the wiring harness. They are designed with details that deliver superior quality and performance.

Learn More >

With more than 60,000 installs, our revamped SMP® Parts App is updated with new tools that make part lookups even easier, including:

- Keyword Search to help find parts and categories more easily

- History function for quick access to frequently searched items

SMP announces the launch of its SMP Cares website, a new site dedicated to highlighting the company’s efforts supporting local communities through service, volunteerism and donations. This website will serve as a resource for news and upcoming events.

Auto manufacturers receive as much as 25GB of data per hour from your vehicle and get to decide where that data goes. Access to vehicle data is mission critical for us. That’s why we are working with the Auto Care Association and Automotive Aftermarket Suppliers Association (AASA) to raise consumer awareness of this issue and support industry advocacy efforts. Help us protect our industry and ensure consumer choice.

It’s Your Car. Your Data. And it should be Your Choice.

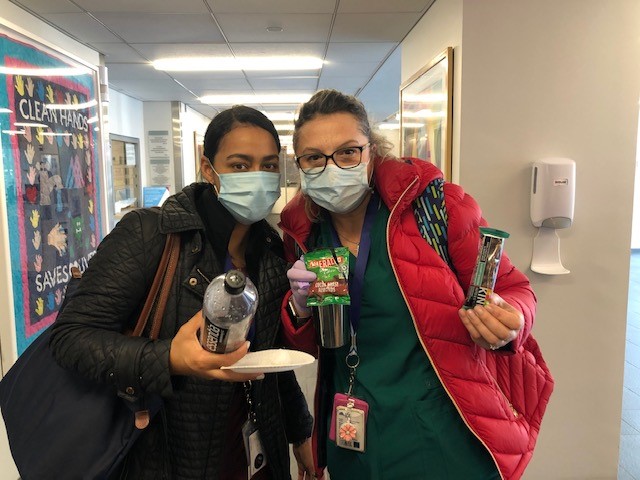

Standard Motor Products, Inc. expressed support and gratitude to each healthcare worker for the work they are doing every day to combat COVID-19 in the local Long Island City neighborhood.

Replacing the Engine Oil Cooler on a F-250 with a 7.3L Powerstroke engine is a complicated job. In this video, our master technician shows you how to perform job correctly.

To account for the burgeoning diesel market, we have fully invested in diesel. Today, BWD® Diesel offers thousands of diesel parts across hundreds of unique diesel categories for popular applications including medium-duty trucks.

Do you have an idea for a part that we should offer? We want to hear from you directly.